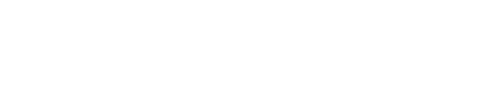

A Comprehensive Guide On The Versatility of Air Operated Double Diaphragm Pumps

Air Operated Double Diaphragm (AODD) pumps are incredibly versatile and reliable tools widely used across various industries. Their unique design and operational capabilities make them suitable for handling a range of fluids. They can handle highly viscous to corrosive substances. Here’s a comprehensive guide on AODD Pump versatility and the reasons behind their extensive application.

How AODD Pumps Work

In Air Operated Double Diaphragm pumps, there are two diaphragms connected by a shaft. When air is supplied to one diaphragm, it pushes the liquid out of the chamber while simultaneously pulling the other diaphragm to draw in fluid. This alternating action creates a continuous flow, ensuring that the pump can handle both small and large volumes efficiently. The air valve system is crucial as it directs the compressed air to the appropriate chamber, maintaining the pump’s rhythmic operation.

Key Features of AODD Pumps

Self-Priming: These pumps can start operating without needing to be filled with liquid first. This self-priming capability is especially beneficial in applications where the fluid source is at a lower level than the pump.

Run Dry Capability: Unlike many other pump types, they can run dry without damage. This feature is particularly useful in scenarios where fluid flow may be intermittent.

Solids Handling: Air Operated Double Diaphragm pumps can handle fluids containing solid particles. This makes them ideal for industries like mining and wastewater treatment, where slurry and sludge are common.

Variable Flow and Pressure: The flow rate and pressure can be easily adjusted by varying the air supply, providing precise control over the pumping process.

Explosion-Proof: Because they operate on compressed air rather than electricity, AODD pumps are safe for use in explosive or flammable environments, such as chemical processing plants.

Applications Across Industries

Chemical and Petrochemical: These pumps are resistant to a wide range of chemicals, making them suitable for transferring acids, solvents, and other corrosive substances. Their ability to handle hazardous materials safely and effectively is a significant advantage.

Food and Beverage: In the food industry, these pumps are used for transferring ingredients, additives, and finished products. Their gentle pumping action ensures that delicate products are not damaged during transfer.

Pharmaceutical: The hygienic design of certain Air Diaphragm Pump allows for easy cleaning and sterilization, meeting the stringent sanitary requirements of the pharmaceutical industry.

Water and Wastewater: They are commonly used in wastewater treatment plants to handle sludge, slurries, and other abrasive materials. Their ability to manage solids makes them invaluable in these settings.

Mining: The robustness and durability of Air Operated Double Diaphragm Pumps make them ideal for the mining industry, where they are used to transfer slurry, dewater mines, and handle abrasive materials.

Maintenance and Care

Proper maintenance of these pumps is crucial for ensuring their longevity and optimal performance. Regular inspection of diaphragms, valves, and seals is necessary to prevent wear and tear. Lubricating the air supply components and ensuring the pump is operated within its specified limits can also help in maintaining efficiency and reliability.

Wrapping Up

The versatility of Air Operated Double Diaphragm pumps lies in their robust design, operational flexibility, and ability to handle a wide range of fluids and conditions. Their application across diverse industrial operations including harsh chemicals, delicate food products, or abrasive slurries. Additionally, their ease of maintenance and safety features further enhance their appeal. If you are planning to invest in a pump, it is the best option!

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.