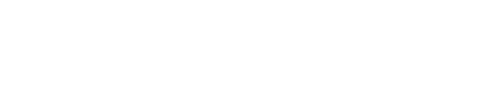

5 Factors to Keep in Mind When Choosing AODD Pumps

Air-operated double-diaphragm pumps (AODDs) are among the most adaptable in industrial settings. They have proven reliable in various industries, including food and beverage, mining, construction, pharmaceuticals, and chemicals.

An air-operated double diaphragm pump propels fluid by alternating and repeating back-and-forth movements (strokes) of two flexible membranes or diaphragms positioned on the same shaft. It is almost leak-free unless one of the diaphragms breaks. Diaphragm failure is uncommon in double diaphragm pumps because the diaphragms wear less than those in mechanically driven diaphragm pumps.

5 Considerations When Choosing AODD Pumps

What liquid would you like to push with an AODD pump?

The most important factor in preventing corrosion of wetted parts and wear and tear on pumping equipment is the type, content, and character of the fluid. The distinguishing characteristics include solid content, pH level, viscosity, density, specific gravity, and abrasion factor. Different fluids include:

- Flammable fluids.

- Corrosive fluids.

- Abrasive fluids

- Toxic fluids.

- Shear-sensitive fluids

For example, using an aluminum pump for abrasive fluids might be a costly error because aluminium has weak corrosion and abrasion resistance. In this scenario, the best option would be polypropylene casting. PVDF is recommended in chemistry settings due to its high chemical resistance to acids and bases, whereas PTFE is very chemically compatible but has low abrasion resistance.

2. Flow rate.

The flow rate is proportional to the draining time of the machine. The flow rate is taken into account first while calculating pump size. To get higher flow rates, utilize a larger pump with larger port sizes, such as suction and discharge connections, and vice versa. The higher the flow rate, the shorter the draining time. When sizing an AODD pump for best efficiency and longevity, it is common practice to move up one port size if possible.

3. Pressure Conditions

Analyzing the requirement for proper pressure conditions within the AODD chambers aids in the selection of the suitable pump size. Suction Pressure refers to the pressure at the pump inlet. AODD pumps are self-priming, making them suitable for both flooded suction and suction lift circumstances.

Because increased pressure provides a faster flow rate, it must also be managed. Excessive pressure might impair the lifting capacity of the suction valves. This may cause downtime.

The discharge pressure, also known as delivery pressure, affects the height to which the fluid is pushed. It is computed in addition to frictional losses.

4. Flow viscosity.

Viscosity is the resistance to flow. AODD pumps are noted for being gentle on the fluids they pump, as opposed to other types of pumps.

Their sealless design reduces maintenance requirements while reducing shearing or degradation of the goods being pumped.

It is vital to understand the viscosity of the liquid. For liquids with above 5000 cps, 1.5″ is recommended. For convenience, AODD pump manufacturers provide a viscosity correction factor for various viscosities based on pump size.

For high-viscosity fluids, the flow rate must be reduced by applying a viscosity adjustment factor to the standard curves.

5) Temperature

AODD Pump materials have temperature limits. In addition to chemical compatibility and pump materials, temperature plays an important role in the pump’s lifetime.

To ensure that the pump material is most suited for a certain application, we must know both the operating temperature and the climatic conditions.

Rubber and thermoplastics have different temperature ratings. Fluorocarbons, for example, can withstand temperatures of up to 177 degrees Celsius. Teflon may be beneficial in cold conditions, such as those seen during CBD production.

The neoprene diaphragm, on the other hand, has a temperature limit of less than 100°C.

Conclusion

AODD pumps outperform alternative mechanically powered pumps due to their durable construction, reduced maintenance needs, and increased application variety. Air-operated diaphragm pumps have a long operating life, even in harsh situations, because of their reduced diaphragm wear.

Because there are no internal seals or moving components that require lubrication or cooling, an air-operated double diaphragm pump may run dry at all times. AODD pumps are self-priming and can have a suction lift of up to 8 meters.

Ceracin has been the leading manufacturer of air-operated double-diaphragm (AODD) pumps in India. We provide a variety of solutions to meet specific market application needs. Trust in our world-class technological expertise and innovation to provide industry-leading durability and performance. We offer the most versatile product line to meet the needs of a diverse set of market applications.

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.