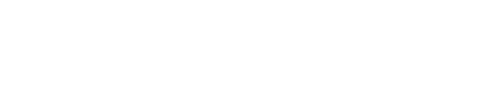

5 Key Factors to Consider When Choosing the Right Barrel Pump for Your Needs

A barrel pump is a portable pump made especially to make it easier to move fluids from barrels safely and effectively. Barrel-transfer pumps can be applied to a variety of barrel-style containers. Also known as drum pumps, barrel pumps are made to offer a simple, secure means of transferring or dispensing almost any chemical from containers like barrels or drums. Whatever we call them, there are a wide variety of models, tube lengths, and accessories made to meet a wide range of industry needs. In this blog, we’ll discuss major factors to consider when purchasing a barrel or drum pump.

Here are the Things To Take Into Account While Choosing a Barrel Pump

A few factors must be taken into consideration to ensure that the barrel or drum pump you choose will perform the tasks you need it to. Barrel pumps are extremely versatile pieces of equipment with a wide range of uses. Some are manually operated, dispensing the fluid with handles, levers, or plungers.

Type of Container

Considering the kind of container to use the barrel or drum pump with should be your priority. Choosing the appropriate length of hose is also important, since if it does not reach the bottom of the barrel, the barrel cannot be emptied. These factors together account for the size of the pump needed to complete the task.

Fluid Type

The type of fluid that the barrel or drum pump will be moving is the next thing to think about. When transferring edible fluids, such as cooking oil, ketchup, chocolate sauce, or mayonnaise, you need to ensure that every single component that the edible fluid will come into contact with is sterile and composed of food-grade materials. A chemical barrel pump designed to withstand the properties of the chemicals being pumped is required when transferring caustic or hazardous fluids.

Viscosity of fluid

You should also take the fluid’s viscosity into account. For example, a pump made to move water may find that treacle is too viscous for it to handle. It is imperative to ensure that any particulates present in the fluids you are pumping, such as old engine oil, won’t harm the pump’s internal components. It’s important to consider if the pump will need to be able to transfer different kinds of fluids. If so, you should carefully consider how quickly the pump can be cleaned to prevent cross-contamination; even with a food-grade pump, you don’t want ketchup in your raspberry coulis or chili sauce in your honey. Keeping your chemical barrel or drum pump free from this form of cross-contamination may be even more important if you are transporting chemicals.

Last Words

Selecting the appropriate barrel pump ensures a trouble-free future because of its simple operation. This is also one of the reasons barrel or drum pumps are used widely. If you take your time choosing your barrel or drum pump, you’ll have a dependable, adaptable piece of machinery that will operate silently and effectively for many years to come

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.