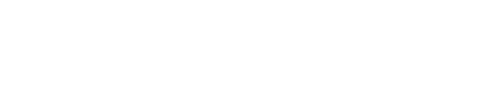

How does AODD Pump Work?

The diaphragm pump is a double diaphragm positive displacement pump that operates on compressed air. AODD pump uses a pneumatic valve to move compressed air between the pump’s two sides.

Diaphragm pumps can handle liquids of varying viscosity and liquids containing suspended particulates. Air-operated diaphragm pumps have unique designs and can handle very harsh chemicals.

The Operation of an AODD Pump:

AODD pumps are reciprocating positive-displacement pumps. They work by displacing fluid from one of its two liquid chambers with each stroke completion. To work, diaphragm pumps require a specific amount of pressure (measured in pounds per square inch) and air volume (measured in cubic feet per minute) to deliver the appropriate amount of fluid.

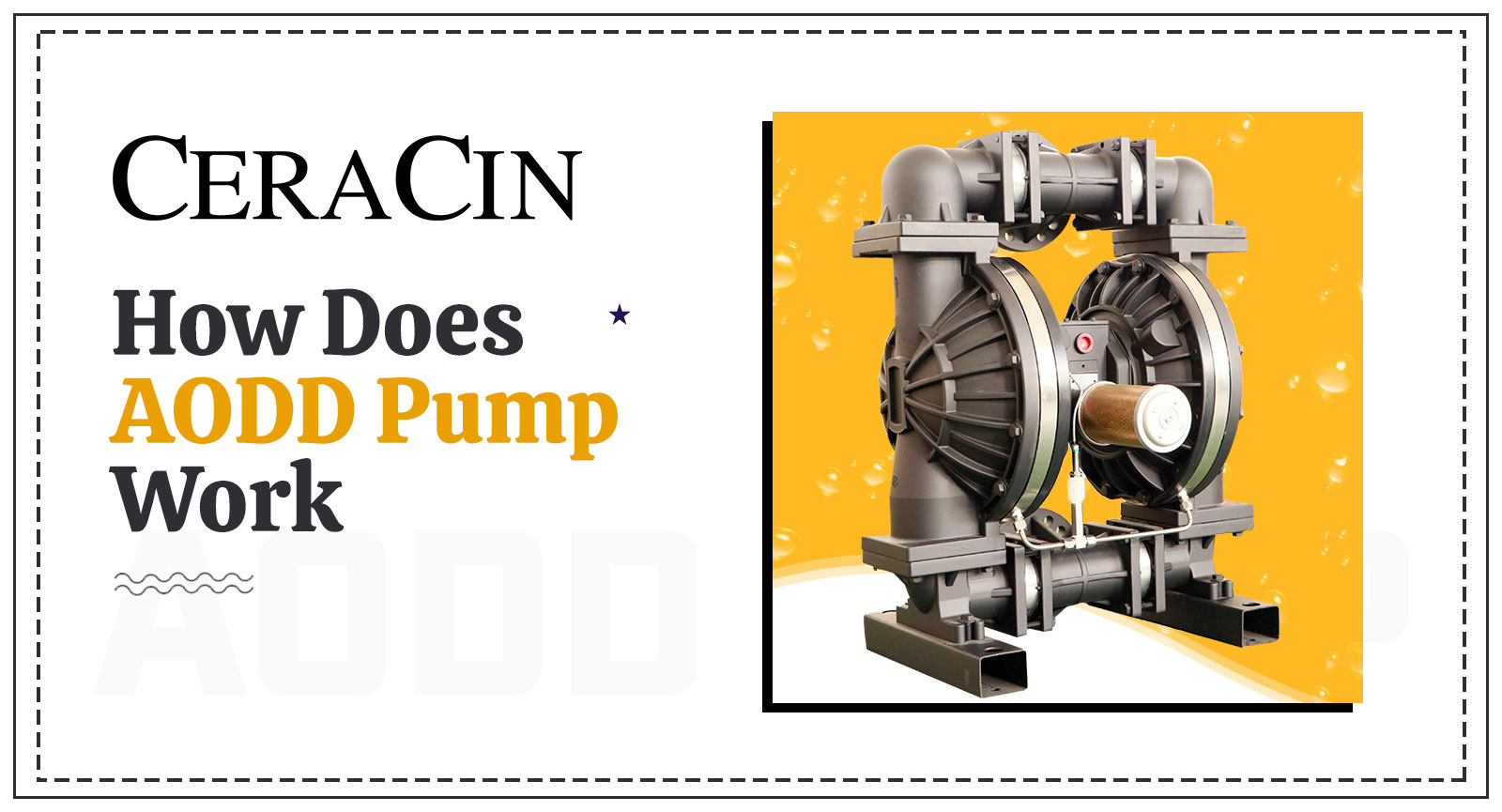

Due to the simple design of the AODD pump, there are only a few dynamic wetted parts: the two diaphragms joined by a single shaft, the two intake valve balls, and the two output valve balls. The diaphragms serve as a barrier between the compressed air supply and liquid.

Driving the diaphragms using compressed air rather than the shaft balances the load on the diaphragm, removing mechanical stress from the operation and increasing diaphragm life. This also permits the valve balls to open and shut against the valve seats, directing liquid flow. This simple design and operation allows the operator to easily determine the appropriate pressures and flows to maximize its functioning.

The AODD pump starts operating when the air distribution system delivers the air supply to the right air chamber and the rear side of the diaphragm. This pulls the diaphragm away from the central block and toward the liquid chamber, drawing the opposing diaphragm inward.

When the pressurized right liquid chamber has reached its liquid capacity, the air valve delivers compressed air to the back side of the opposite diaphragm. This pulls the right diaphragm toward the middle block while pushing the left diaphragm away from it. This seals the intake valve ball on the other side while raising the discharge valve ball from its seat which causes the liquid to flow through the discharge manifold.

The process is repeated on the opposite side with the liquid chamber filling. The pushed air redirects the diaphragms and the resulting pressure drives the discharge valve ball off its seat as the liquid passes through the discharge manifold.

As the AODD diaphragm pump returns to its starting point, each diaphragm has completed one suction and one discharge stroke, which completes one pumping cycle.

The importance of selecting the correct AODD pumps

AODD pumps can handle a wide range of fluids, flow rates, and viscosities. Also, it can operate in many applications. Ceracin designs and manufactures air-operated double diaphragm pumps that satisfy the needs of industrial sectors. Our technical and sales teams are available to assist with selecting a new pump and advise on various accessories and replacement components.

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.