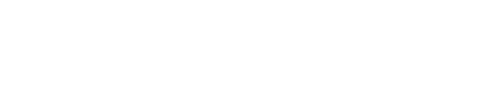

All You Need To Know About A Dosing Pump: A Comprehensive Overview

Dosing pumps, also known as dosage pumps or metering pumps, are positive displacement pumps used to inject chemicals or other substances into a stream of water, gas, or steam. A Dosing Pump is typically compact and offers extremely precise flow rates for optimal control. They are the central component of an integrated metering system for autonomous chemical dispersion.

Moreover, these pumps dispense specific amounts of fluid while also measuring flow control. To transfer the fluid, they use expansion and contraction chambers. Metering pumps can pump a wide range of liquids, including corrosives, acids, and bases, as well as slurries and viscous liquids.

What Is the Use of a Dosing Pump?

These pumps are employed in industrial facilities, agriculture, manufacturing, medical laboratories, and mining activities, in addition to water purification and the food sector. Pumps are typically used to transfer a caustic chemical or an acid into a water storage tank to neutralize the pH. Dosing pumps are also frequently used to kill microorganisms as chlorine pumps. Certain variants are intended for extreme conditions such as high temperatures and high pressure.

Working Process Of A Dosing Pump

This pump pulls a certain volume of liquid into its chamber and injects the chemical into a tank or pipe containing the fluid to be dosed. It is powered by an electric motor or an air actuator and contains a controller that controls the flow rate and turns the pump on and off. Some models have more advanced control systems.

Different Types Of Dosing Pumps

There are four types of such pumps designed by Dosing Pump Manufacturers in India for a variety of pressures, substances, and uses. They differ in terms of pumping activity and mechanism.

Diaphragm (constant injection) pumps

These fill and empty their chambers using a diaphragm, piston, and valves on both the input and output. Drawing in the piston fills the chamber, and a predetermined amount of chemicals is injected at a predetermined speed, which is usually a percentage of the maximum flow rate.

Diaphragm (pulse injection) pumps

They employ the same principle as diaphragm pumps, but instead of a constant flow rate, a solenoid coil takes up the chemical and injects it in pulses. The flow rate is defined as the period between pulses.

Lobe pumps

Allow a specific volume of fluid to pass via meshing gear impellors. It is not as precise as a diaphragm pump and is only appropriate for high-viscosity fluids that self-lubricate to reduce wear.

Peristaltic pumps

Dosing with these pumps is quite precise. A flexible bent tube allows the fluid to pass through, and the flow is regulated by a roller on the exterior that moves via a mechanical arm.

Major Applications of Dosing Pumps

Dosing pumps are utilized in a variety of applications. The pumps are mostly used to modify the pH of water as well as to protect it from corrosion and precipitation. Disinfectants, flocculants, and scale inhibitors are frequently mixed using the pumps. Of course, the pumps can be utilized for other reasons as well.

A few examples of its applications are provided below.

- Process water disinfection

- Chemical industrial uses

- Food and drinks

- Irrigation

- Cleaning-In-Place

- Ultrafiltration

- Disinfection and pH balancing

In conclusion

Dosing pumps have low volume, and adjustable discharge rates and are used to inject various chemicals and viscosities of solutions. However, choosing the correct dosing or metering pump for your process might be difficult. So, for assistance regarding these pumps, you can visit our website Ceracin. Additionally, we are one of the leading Dosing Pump Exporters in India that manufacture a variety of pumps including AODD Pump. For further you may contact us!

Ceracin

Ceracin has expertise in industrial pump manufacturing since 2016. We are committed to provide our nation with the highest quality pumps at competitive prices.