Air Operated Double Diaphragm Pumps

Your Versatile Pumping Solution!

We have a long and proud history givin emphasis to environment social and economic outcomes to deliver places that respond too the complex global forces shaping our future

AODD pumps are the positive displacement pumps suited to applications that need a wide range of pumping options. These pumps utilise air supply to change the discharge pressure from 0 psi to the maximum pump rating. Diaphragm pumps are more durable and dependable than other pump types because they can run dry without damaging the diaphragm. The life span of AODD pumps depends on the manufacturing and raw material quality. CERACIN has some highly skilled engineers, professionals, and a labour force that effectively designs and fabricates these pumps for maximum outcomes. Once the manufacturing parts get over in the facility, we run thorough tests on these pumps to ensure their productivity at different places. We are the prime Air Operated Double Diaphragm Pumps Manufacturers In India, thanks to our client-based policies.

Know More Features & Applications

Features

Our Pumps Comes With Exclusive Features!

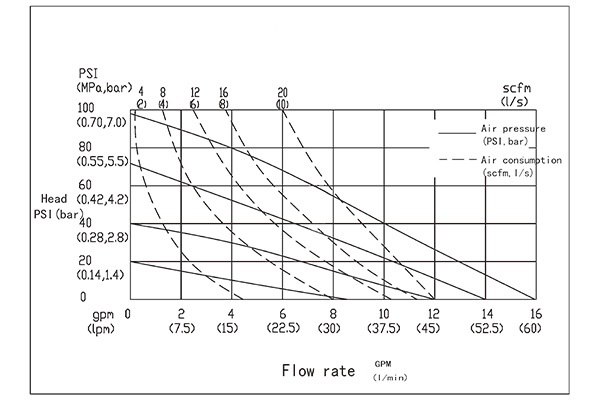

- The flow rate and the head gets controlled by the air pressure.

- Assurance check on the deadheading, priming, and sealing.

- Improved air circulation design with minimal air usage.

- Completely made of plastic, with rugged air system and resistant to corrosion.

Applications

Various Applications In Different Industries!

- Surface Finishing & Pharmaceuticals

- Printing/Ink Supply

- Chemical & Paper Industry

- Sewerage & Food Industry

- Automotive & Paper Industry

Explaining The Complete Cycle

Compressed air is sent behind one of the two diaphragms in the pneumatic distribution system, which then pushes the fluid toward the delivery circuit.

We have a long and proud history givin emphasis to environment social and economic outcomes to deliver places that respond too the complex global forces shaping our future

At the same time, the diaphragm on the other side is being drawn under pressure by the shaft that links it to the diaphragm. The flow rate regulation on the pump discharges the air behind the diaphragm into the environment, while a pressure decrease in the fluid chamber sucks the fluid from the suction circuit.After reaching the stroke limit with the diaphragm under pressure, the distributor switches the diaphragm air side inputs to the chamber, placing the diaphragm under pressure and in discharge. Each diaphragm in the pump has completed one air discharge and one fluid delivery stroke by the time it returns to its initial starting position. A pumping cycle consists of this series of actions. CERACIN indigenously manufactured AODD pumps and hence is the top Air Operated Double Diaphragm Pumps Supplier in PAN India.

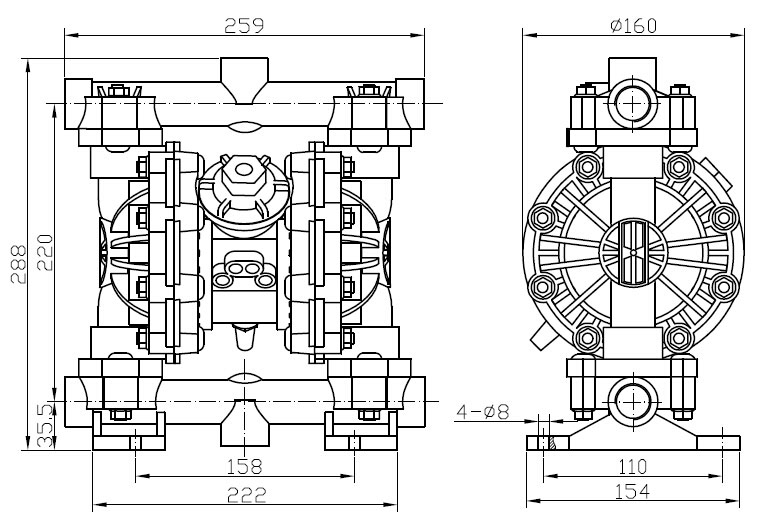

Other Informations Technical Specifications

| TECHNICAL SPECIFICATIONS | |

| Fluid connection | 1/4″ BSP |

| Air connection | 4 mm |

| Max flow-rate* | 8 l/min |

| Max air pressure | 6 bar |

| Max delivery head* | 60 m |

| Max Suction Lift Dry* | 3 m |

| Max Suction Lift Wet* | 9,8 m |

| Max Solid passing | 2 mm |

| Noise level | 62 dB |

| Max Viscosity | 5.000 mPas |

| Material | PP/PVDF+CF/POMc |

| Displacement per Stroke | 18 cm³ |

| * Depending on the materials All threads are internal threads All values mentioned are non-binding guide values | |

- Our AODD pump is portable and easy to assemble. Simple controls allow for easy installation and usage.

- The design of the pump enables a high suction lift with the self-priming feature.

- The compatible exterior components of an AODD pump make it easy to operate while submerged in the liquid.

- A simple change in the air supply allows our AODD pumps to operate at flow and discharge pressures as high as 120 psi!

- The pump has no close-fitting or spinning elements, making it easy to move liquids with a high solids concentration.