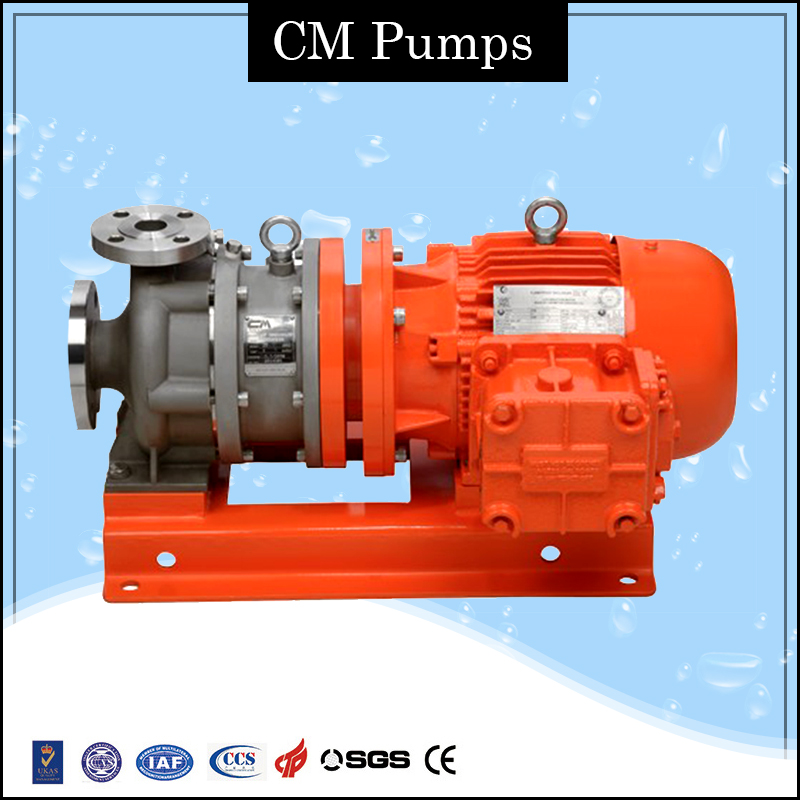

Magnet SS Drive Pumps

To Transfer The Corrosive Liquids In An Effective Manner!

We have a long and proud history givin emphasis to environment social and economic outcomes to deliver places that respond too the complex global forces shaping our future

There is no longer the requirement for shaft sealing when using a magnetically driven pump, which is a specific form of a magnetically powered chemical process pump. Due to the fact that there are no mechanical seals ( sealless pump ), seal-fluid containers, or cooling lines connected, this results in a significant reduction in the original cost of the pump as well as in the day-to-day running expenses. The stainless steel magnetic pump is so versatile that it can easily perform any task given any liquid. Ceracin manufactures these pumps in close collaboration with highly competent professionals and engineers to deliver high-quality products. We are the leading Magnet SS Drive Pump Manufacturers thanks to the dedication and expertise of these professionals.

Know More Features & Applications

Features

Our Pumps Comes With Exclusive Features!

- Great chemical resistance

- Lack of leakage and emissions

- They require little maintenance and replacement parts costs also get decreased with time.

- Magnetic drive pumps feature a unique sealless design making them ideal for pumping corrosive and hazardous liquids.

Applications

Various Applications In Different Industries!

- Toxic

- Hydrocarbons

- Corrosive chemical

- Pyrophoric and others

- Noxious and carcinogenic

Magnet SS Drive Pumps

Ensuring Extra Sealing To Corrosives!

We have a long and proud history givin emphasis to environment social and economic outcomes to deliver places that respond too the complex global forces shaping our future

When using a typical magnetic drive centrifugal pump or mag-drive water pump, some kind of seal is required to prevent the pumped medium from escaping around the pump shaft and losing pressure. This is particularly important when the medium is under high pressure. To ensure that, a compressible cushioning material gets wrapped around the pump shaft and placed in a stuffing box. A gland nut may be used to gradually tighten the packing material as it wears or settles in the stuffing box (the casing’s hole). Ceracin supplies these centrifugal magnetic pumps in a secured manner to our clients at their given location. We not only supply PAN India but in overseas nations as well. We are the top Magnet SS Drive Pumps Exporters In India. Further, if you wish for custom specifications, we are all there for you!

Request a Quote

Fill all information details to consult with us to get sevices from us